DOUBLEBRAID IS THE LATEST ADDITION

HOMENEWSAFTERMARKETMASTS, SPARS, SAILS & RIGGINGDOUBLEBRAID IS THE LATEST ADDITION

24 Jun 2021

Share

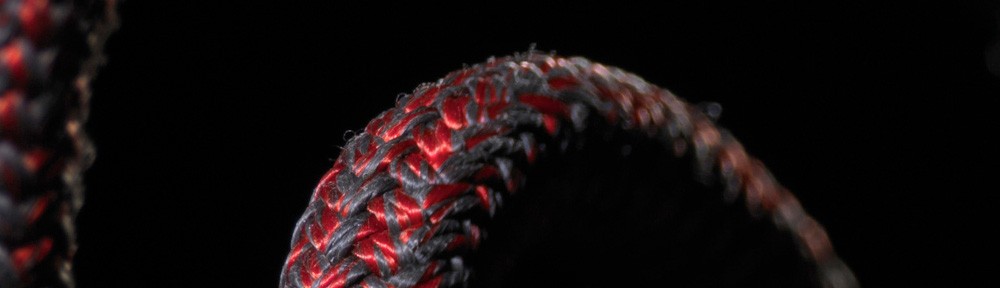

Marlow’s Doublebraid can be used for a variety of purposes onboard

INDUSTRY DATABASE

MARLOW ROPES LTD

Blue Ocean Doublebraid is Marlow Ropes’ latest addition to its eco-conscious Blue Ocean product range, manufactured from sustainable materials.

The heat-set braid-on-braid Doublebraid is made from 100% recycled waste plastic bottles and follows the release of the company’s Blue Ocean Dockline.

Since the launch of the Blue Ocean Dockline in 2018, more than half of Marlow’s yachting range is now manufactured using sustainable materials.

The latest Blue Ocean product can be used for a variety of on-board applications.

It is available on a reel as standard and also as spliced finished assemblies on request.

“It offers flexibility and easy handling for all sailors, and now has the reassurance of being sustainably manufactured,” explained Marlow’s leisure marine director, Paul Honess.

Carbon footprint

“The addition of this new product demonstrates Marlow’s on-going commitment to sustainable manufacturing by reducing and eliminating our negative environmental impact through the introduction of the Blue Ocean product range and company-wide Blue Ocean initiatives which focus on reducing energy consumption, waste and the company’s carbon footprint.”

And he explained it’s important to Marlow to take responsibility and become more sustainable while providing customers with more rope options.

“We have worked hard over the last couple of years to eliminate plastics from our ranges, lower our carbon footprint and introduce sustainable materials,” he added.

“With half of our range now made using these sustainable materials we are getting closer to achieving our target of using 100% reliance on recycled materials by 2030.”