Spinlock extends the use of ceramic coated parts

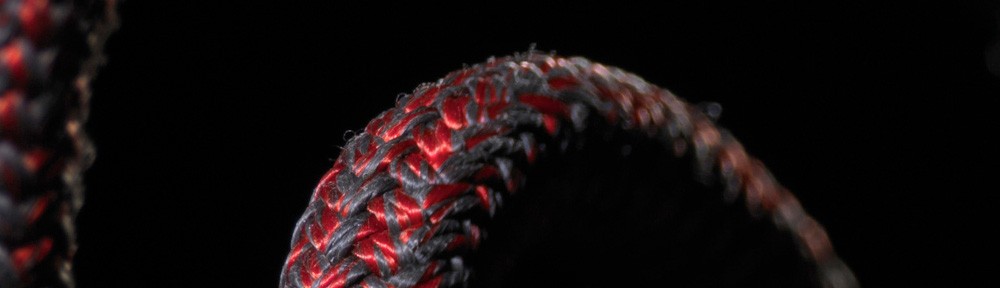

Spinlock is using ceramic coated parts in more of its clutches

The movement to smaller diameters of rope on board, increased loads and more powerful sails continues, with increased demands on rope holding products.

As such, Spinlock has now extended the use of ceramic jaws and bases across its XX0812, XCS and XTS clutches.

“Confidence in the product is very high,” explained Doug Vincett, Spinlock technical sales and support. “Ceramic is being used in a lot more products, it gives a better grip when using modern lines.”

And he explained how the ceramic coatings allow the cam or jaws to engage quicker on a loaded line, taking up the load faster and with less creep.

On smaller dimeter lines this is more noticeable, however once engaged the ceramic coated cam or jaw offers improved, consistent holding.

The ceramic coated parts also offer increased resistance to abrasion and wear. They are available as upgrade kits for existing products as well as specified in new product.

Spinlock has also developed its TSR organisers for diverting lines from clutches and jammers and launched a larger version of its Rig Sense.

The organisers have a lower and shorter sheave however the holes can be matched to previous products.

The 0508 Rig Sense is for rigging of 5mm to 8mm in diameter and gets around the problem of accuracy explained Mr Vincett.

“It covers small keelboats,” he said. “It’s great for riggers and also the sailor. It comes with a free app, data can be recorded and sail settings, which rig tension to use in which wind speeds.”

via Boating Business | Spinlock extends the use of ceramic coated parts.